HYDRAULIC COUNTER-SUPPORT

This is ideally suited to vertical axis machine-tools for mass-production machining. It locks cubes and cradles, with high rigidity and great accuracy. It considerably reduces the re-tooling time. The counter-support is very rigid, as it is locked hydraulically on the same principle as the tables. The counter-support may be of different dimensions, depending on the model of table it is matched to and also on the length of cubes or cradles to be held. O.M.R. do not exclude the possibility of designing hydraulic counter-supports to be adapted to non-O.M.R. tables.

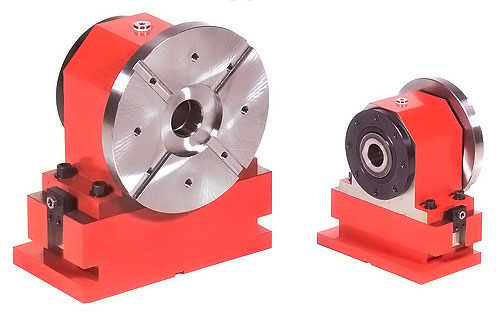

HYDRAULIC/PNEUMATIC TAILSTOCK

The hydraulic-pneumatic tailstocks have been designed and built modularly to be adapted simply to any O.M.R. table model, whether standard or special. This system facilitates the possibility of adapting the O.M.R. tailstocks to pre-existing tables, even if they are not of O.M.R. manufacture. The O.M.R. tailstocks operate with hydraulic-pneumatic system. The barrel permits the application of morse 3 or morse 4 cone bits with standard 50 mm stroke. Upon customer request, it is possible to have strokes of different dimensions. The O.M.R. tailstocks have a separate base and body. With this system, it is easy to align the tailstock to the table centre and to adapt it to other tables by substituting the base only. Both base and body are made from high quality cast-iron, whereas the barrel is made of spindle-grade thermally treated and ground material. All tailstocks are provided with a hydraulic pipe, 5000 mm length, and a quick disconnect coupling for extraction. All tailstock models can be controlled by pushbutton or pedal.

HYDRAULIC POWER UNIT

This is an essential element for locking the table and for the to-and-fro movement of the tailstock barrel. The O.M.R. hydraulic power units can be delivered without electric cabinet when the table is installed by the machine-tool manufacturer while making/assembling the machine-tool itself. In this case, the hydraulic power unit is controlled by the electric cabinet of the machine. When the tables are managed by their own control, the hydraulic power unit is complete with its own electric cubicle, which also houses the table and tailstock NC, drives and controls. All O.M.R. hydraulic power units are preset for controlling the tailstock or counter-support. In agreement with our technical office, the hydraulic power unit can be configured to also operate other auxiliary systems attached to the machine on which the table is going to be installed.

NUMERICAL CONTROL

The SIAX-110/C is a small NC with great performance, distinguished by its compactness and economy. It was devised to solve the problems linked to the automation world, and it was tailored by O.M.R. – through the electrical/electronic design of the application and through programming the necessary machine PLC logics – for interfacing itself to the rotary table operation

The electronic equipment is supplied as follows:

Supply of numerical control model SIAX-110/C with 1-axis version, or 2-axis version if it is to drive a 2-axis swivelling table, with an LCD display with 4 lines of 20 characters (LED back-lit), with table management through external start or by M code from the machine-tool CNC.

A1. As an alternative to the above, a SIAX-110/C numerical control can be delivered without panel, but includes a remote keyboard with an LCD display with 8 lines of 40 characters, plus a 4 m long interconnection cable.

HARDWARE features

MEMORY: 32 to 256 Kbytes for user programs, 16 to 64 Kbytes for PLC and messages.

DIGITAL INPUTS: 16 to 32 (48 if there are only 16 outputs), 24 Vdc, optoisolated.

DIGITAL OUTPUTS: 16 to 32 (48 if there are only 16 inputs), 24 Vdc/100 mA, optoisolated.

INCREMENTAL ENCODERS: 1 or 2, 5/12V, Push Pull, Line Driver, 200 KHz

ANALOG INPUTS: 4-12 bits, 0-5V.

ANALOG OUTPUTS: 1 or 2, 12 bits, ±10V.

SERIAL LINK: two RS232 links (or one RS232 + one 422).

KEYBOARD: polyester 41 keys + 15 function keys that can be tailored.

DISPLAY: LCD 4×20, LED back lit.

PROTECTION CLASS: IP65

POWER SUPPLY: 15 Vac or 24 Vdc, max. 1.2 A

CONNECTIONS: at the back, with cup connectors.

DIMENSIONS: L=200 mm × H=160 mm × D=105 mm.

SOFTWARE performance

Management of all types of motor and drive systems.

Management of 20 origins.

Set of 200 special instructions in addition to positioning.

Parametric cycles.

Cross referenced tables; mathematics (trigonometry, roots, comparisons).

Management of 250 messages.

Complete tests toward the external world.

Interface to PC.

Modem connection.