All our tables can be interfaced to the CNC of the machine-tools they are mounted on; or they can operate independently from the machine-tool, in which case they are controlled by its own CNC located in an electric cubicle and activated by a trolley-mounted hydraulic power unit.

The tables, based on their end application, size and carrying capacity, can be built with 2 different types of power transmission and displacement:

(1) Tables with mechanical transmission which, depending on their size, have been designed with 2 different movement systems :

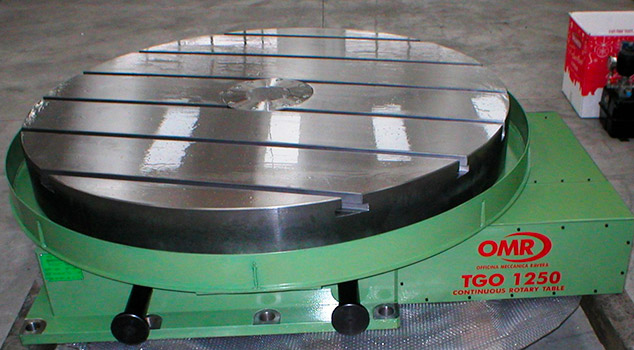

(1A) Horizontal and vertical axis tables with mechanical transmission by screw and crown wheel. Usually these tables have a dimension of up to 1250×1250 mm and a maximum capacity of 10 tons. They are built with axial-radial bearing.

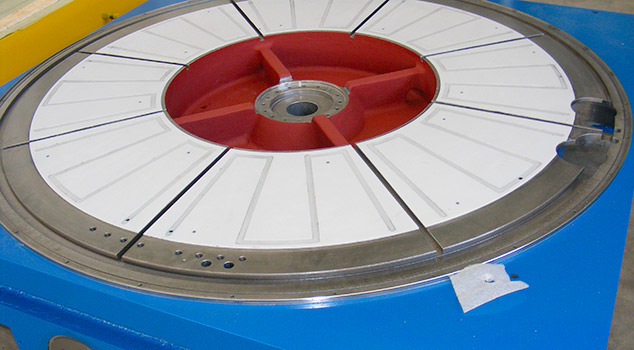

(1B) Vertical axis tables, mainly built for rotation on a scrape-finished race with FORCED OIL-VEIL LUBRICATION. These tables are semi-hydrostatic and hydrostatic, with mechanical transmission by crown wheel and preloaded double pinion gear reducer.

This system is used for medium and large tables with 12 to 70 tonne capacity, either rotary only or revolving and traversing.

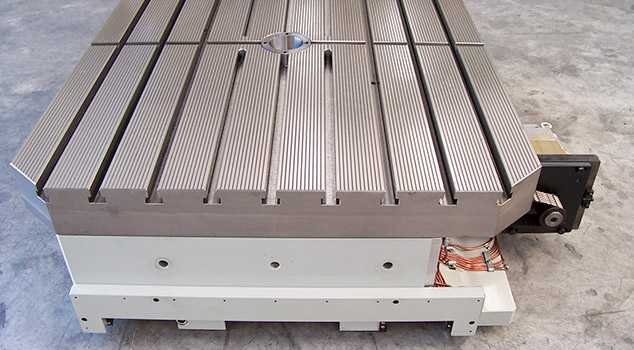

(2) Tables with direct transmission, built with torque motors in collaboration with the best motor manufacturers at a worldwide level.

These types of tables are manufactured principally for turning and grinding.O.M.R. can build tables for turning, drilling and grinding centres, even palletized.

Prior to dispatch, every table is tested geometrically and submitted to work simulations on a CNC test bench which emits a certificate specifying the real accuracies and performance of the table.

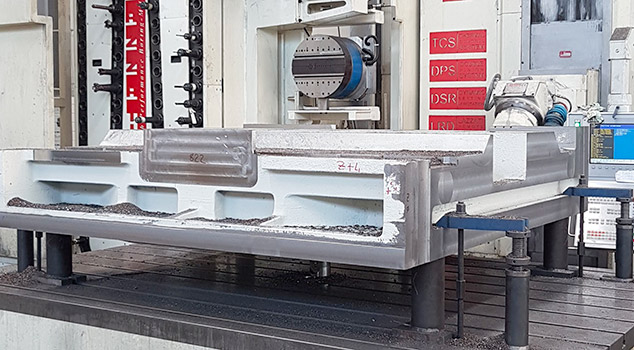

The continuously revolving tables manufactured by O.M.R. are used mainly on work centres, mobile upright milling and boring machines and special turning and drilling machines.

They are subdivided into: